The distinction between Digital printed and Traditional Printed

Water Print Process For Fashion Garments

November 27, 2017

High-Grade knitwear for big brand

December 7, 2017The distinction between Digital printed and Traditional Printed

Digital-printed style

The distinction between Digital printed and Traditional Printed

Digital Printing:

It is using the techniques of modern digital equipment processing and make all sorts of digital design, after dealing with the color separation software by computer, then use the special RIP (Output printed software) through the spray printing system with a variety of special dyes (reactive, acid, disperse, coating) directly spray printed on the base fabrics. After doing some processing on this pattern, we can get some wonderful & vivid patterns.

▲ 2017 Guangzhou Digital printed EXPO.

The advantage of Digital printing:

- No need plenty of water, instead of using ink, reducing waste of chemicals and drain water pollution;

- Without slurry printing, so no environment pollution, no noise pollution.

- Accept any pattern Design, Color;

- Very easy to make sample pattern, and fast;

- Factories are willing to accept various kinds of orders or small order;

- The entire process is automatic, controlled by computer, less of probability of error;

- the production flexibility is strong, colors are rich, delicate and vivid.

The advantage of Digital printing:

- Machine & equipment cost very high;

- Printing & Original material – ink cost high, cause the finished products higher than traditional printing;

- Print can only be printed on the surface of the base fabric, and the effectiveness is not good as water printing.

- The finished printing is not as stable as traditional printing;

- Fabric bulk production not as fast as water printed, it would have color shading like traditional printed while using different machine proceeding.

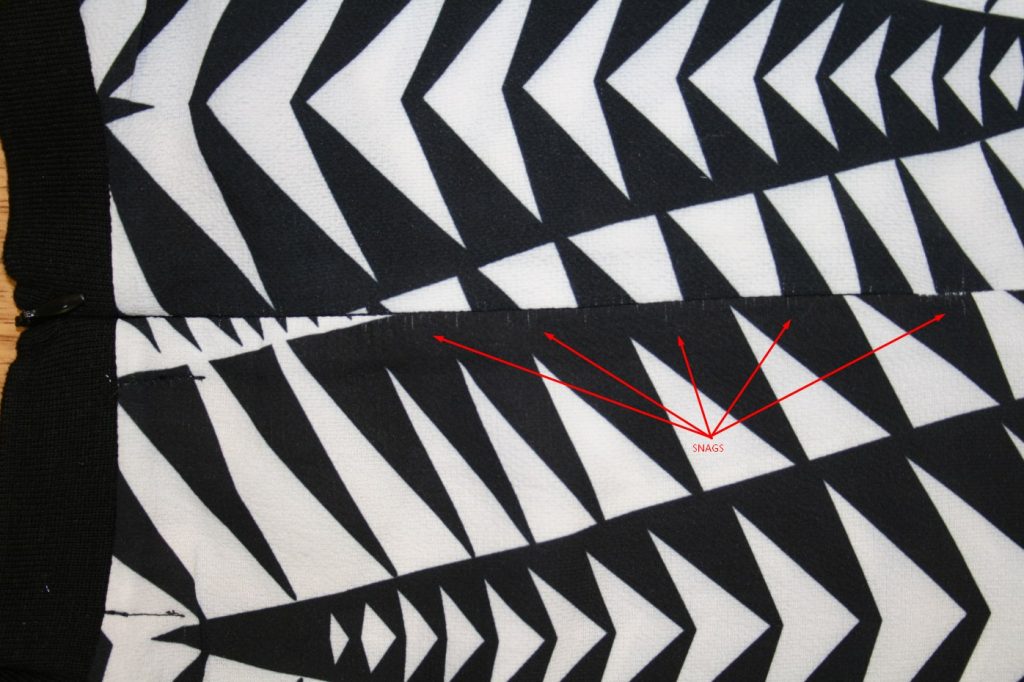

Digital fabric production problem:

▲ The fabric is a dark color, stitching easy to blushing.

▲ Printing difference cause of didn’t make by a same machine.

▲ Fabric easy flawing

Those issues above are normal while digital printing use of dark color and printing on this kind of bubble fabric.

How to make Digital Printing better?

- Choose good quality base fabric, if the pattern is special, use good pigment also very important; Both help a lot while making Digital printing.

- It inevitably gets blushing while making dark color printing, so it is necessary to choose the quality base fabric, strengthen the treatment of the burning, strengthen the cooking and treatment, and to prevent the white point of the cloth from the stem.

According to the difference of dye mediums used and the technological craft made, the mainstream textile digital printing in the market is mainly divided into the following three categories.

ⅠDisperse sublimation dye digital transfer printing

With the use of sublimation dye and the maturity of the jet printer, the first batch digital printing on textile is digital transfer paper printing.

This process uses a digital printing machine to print the dispersive sublimation dye on the special transfer printing paper to form the pattern.Then transfer the paper printing to the base fabrics by a hot pressing process, and the paper printing dye is transferred to textile fabrics in gaseous mode.

This craft printed needs bright and clean sheets of paper, so if used for the base fabric with texture, the process can make out a vivid colour that very nice, and didn’t need steaming after the completion of the printing, washing process, such as simple environmental protection technology, so it is popular using in the market.

The defect of this process is that only the disperse sublimation dye is mature, so it can only be used in polyester fiber fabrics.

In the meantime, because the dye is sublimated by the gaseous sublimation to the fabric, the printing penetration effect is poor, the hand feeling is drier.

In addition, high-quality transfer printing paper is expensive, and these factors limit the space for further development of the process.

▼ video view:

▲ Paper printed

▲ Paper transfer printed

Ⅱ Pigment Digital Jet-printing

Pigment ink can be divided into water-based pigment ink, solvent – based pigment ink and UV – curing pigment ink.

The process needs to pre-treat the base fabric, apply the adhesive, and then use the digital printing machine to spray the ink directly onto the fabric, after heating and drying to then to be finished.

The whole production time is very quick.

This process has the characteristics of wide fiber adaption, short process, almost all fiber fabrics, even film and other materials can be applied.

Very green because of without steaming washing technology, to avoid drain water pollution, the characteristics of pigment ink is the UV resistance (sunlight fastness) is very good, but because of the pigment binder and fiber with physical, by binding together, so the friction and washed poor fastness and a little hard hand feeling.

In addition, because the pigment is suspended in ink with tiny particles, pigment ink is less stable and easy to block.So the process is currently used in homely textile, and the garment printing field is more widely used.

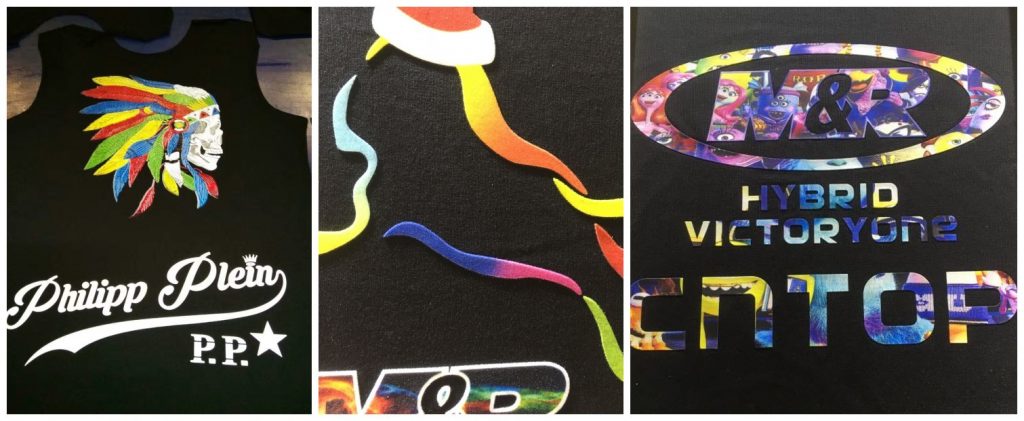

The digital ink-jet printing machine of water-based pigment is mainly used in garment printing fields such as t-shirts.

▼ video view:

▲ Ready made garment shows.

Ⅲ Ink Dyeing Digital Jet-printing

Dye ink is soluble so that it can be completely dissolved in water or solvent, filtered dye ink does not contain granularity composition, so it is not easy to cause nozzle blockage.

The biggest advantage of dye ink printing is that with broad color field and can print bright color.

And the dye composition and printing process are the closest to traditional printing. So the printing effect (penetration, feel, colorfastness, etc.) is closest to traditional printing.

Now it widely applicable on many fabrics like cotton, wool, silk, hemp, fiber fabrics such as polyester, polyamide fiber are the corresponding dye ink can be used for printing, at present this technology has become a mainstream development direction of digital printing.

▲ 2017 Guangzhou Digital printed EXPO.

Comparative Advantage of digital printing and traditional printing

As a major textile manufacturer, China has a long history of traditional printing (plate screen printing, rotary screen printing).

But as an energy-intensive, highly polluting, poor working conditions, the marginal low added value of traditional industries, traditional printing and dyeing technology cannot meet the requirements of today’s rapidly changing market, also is unable to adapt to the country more and more stringent environmental protection policy.

Therefore, the new technology & represented of Digital printing will be the best choice for the transformation of printing and dyeing enterprises.

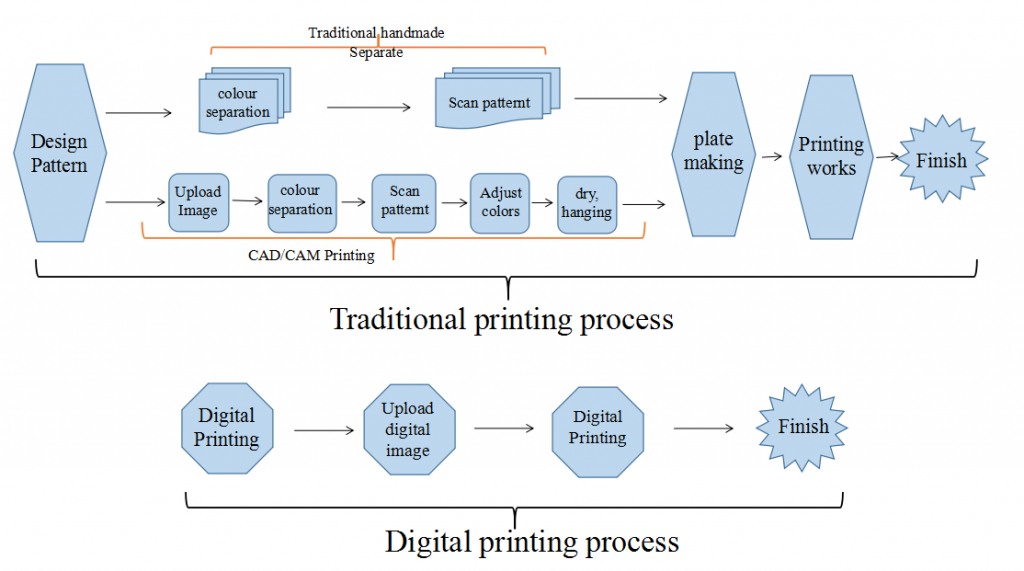

The difference in technique between Traditional and Digital printing:

| Comparison Item | Traditional Printing | Digital Printing |

| Pattern Accuracy | Pattern sometimes Not Accurate, easy to have defective fabric | Pattern Accurately |

| Color limited | Limited on plate/rotary screen | No limited |

| Pattern size limited | 64cm normal use, 118cmhard to use | No limited |

| Pattern Requirement& Effect | Plate/rotary screen cost high | Can make nearly all color |

| Selvage | Sometimes hard to deal with | No this Issue |

| sewage discharge | Cause plenty of sewage | Nearly no pollution |

| Very small order dealing | Cost very high, waste lots of mucilage, fabric, water etc.. | Very easy to handle |

| Time of change pattern or colors | It’s troublesome | Very easy to handle |

| Number of staff | At least 6 staff | One |

| Sampling time | 3-4 weeks | Immediately |

| Speed of production m/min | 50-100 | 50-75 |

The Effect comparison of Digital Printing & Traditional Printing:

▲ Traditional Printing Effect

Development of Printing in future:

Take a perspective of the market, the difference between two big printing process cannot be simply judged by price. The fundamental difference between the two technique lies in the quality, variety, appeared form and technical content of the product.

Traditional printing is not able to produce high-quality products and special characteristic products due to its limitations (Pattern requirement, effect, and pattern size limited etc.). Therefore, the digital printing target market is the high value-added application product consumer group.

Because of the clear market positioning of digital printing, there is a connection and no contradiction between the traditional printing market (No one can take place of others), and both they have their own different consumer groups and application fields.

So Digital printing rarely gets into the traditional print market, given the cost and added value of digital printing.

More Digital printing pic’ show:

More designs of Digital printing & Traditional printing show:

▲ Digital printing

▲ Traditional printing

More details about us, pls check on our website below:

Contact: Jessica Liu

Email: dc@cndc.co

Tel: +86 (020)36012286

Mobile/ WhatsApp: +86 13428886594

1 Comment

I’m truly enjoying the design and layout of your website. It’s a very easy on the eyes which makes it much more pleasant for me to come here and visit more often. Did you hire out a designer to create your theme? Outstanding work!