How to control the satin style quality?

High-Grade knitwear for big brand

December 7, 2017

What We Do

January 18, 2018How to control the satin style quality?

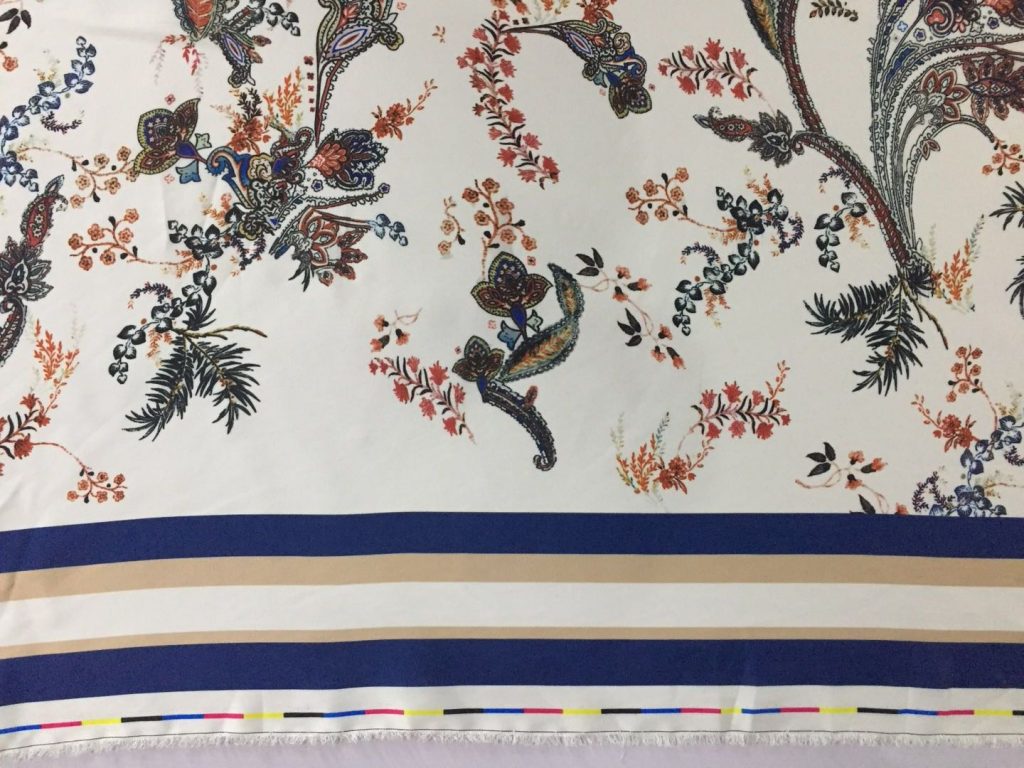

Satin style for reference

How to control the satin style quality?

Satin is softness, glossiness, and luxury.

It is the perfect choice for evening wear and formal occasions.The soft hand feeling and subtle washed finish combine to make a unique and versatile fabric.There is no end to beautiful things being made and sewn with satin – wedding dresses come foremost to my mind, not to say luxury lingerie. Many people confuse silk with satin.

Silk is a natural product but Satin is not. Another frequent mistake people make is thinking of satin as a fabric type alone. Satin refers to the weave which makes the fabric which is also known as satin.

What are the characteristics of Satin?

- it’s ultra smoothness. The fabric has a dull back.

- Very good and soft hand feeling.

3.Colorfastness is very poor, easy to draw yarn.

- The fabric cut edge frays a lot.

- The surface is prone to snagging so it is difficult to maintain the soft smooth surface of satin – so you can say it is high maintenance.

- Water stain: hence if you use the fabric to sew dresses in summer you should be prepared for some staining where you sweat.

What common problem of satin fabric? How to control it?

Issue: Due to the characteristic of satin, it easy to have needle hole on the seam, if draw it will be broken.

Solution: Cannot draw it strongly, with the right needle size to match the grain of the satin fabric can improve the needle hold issue.

▲The needle hole is big.

Issue: This fabric is very slithery, making clothing is hard to control the hem & edge, the hem not easy to make straight.

Solution: Pay more attention while bulking fabric cutting and sewing. If necessary, the fabric needs to trim one by one after bulk fabric cutting; Or the bulk fabric should not be cut together with many pieces/layers.

▲The hem is not straight.

3.

Issue: While doing position printed on satin, should be clear the direction of the printing and the grain of the fabric.

Solution: While cutting position printed on satin fabric, no more than two pieces/layers fabric is allowed.

▲Position printed on satin fabric

4.All the back vent, sleeve vent must be piping.The fabric is very easy to slid edge.

▲If without binding, the edge is very easy to separate.

▲Improve with binding, cannot separate.

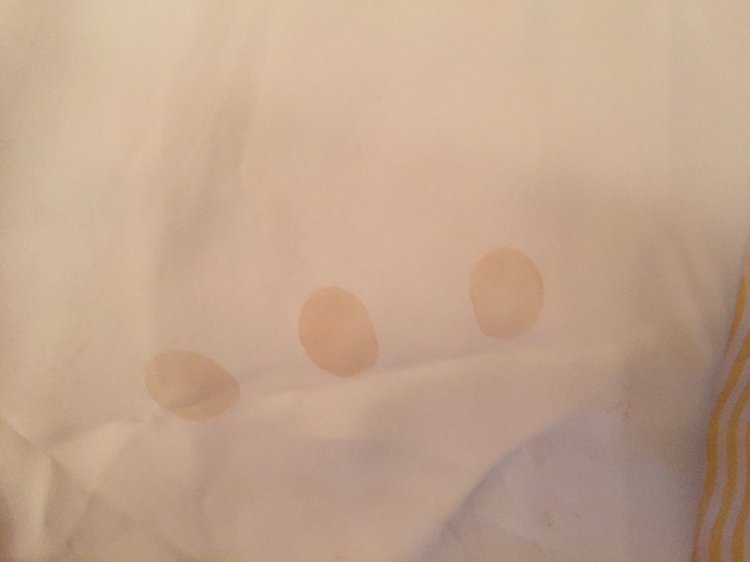

5.Issue: This fabric is easy to get water spots.

Solution: Do not use water sprays when ironing satin. It is always better to press satin from the reverse side.

▲Satin easy to get water spots.

6.Iron shine & puckering

Pressing satin on the surface of the fabric may cause shiny marks – so press on the reverse side or if you are pressing on the surface of the fabric, use a pressing cloth.

7.Needle hole hard to recover:

It may be very difficult to rectify mistakes in sewing satin. If you have sewn a seam wrong and has to resort to ripped stitches, this will mar the look of the dress, as the soft smooth surface of satin will show the stitch marks prominently. I know from experience that picked seams look horrendous on satin.

8 Most satin clothes come with the label – DRY-CLEANED

Satin fabric/styles should take good care of them, cannot wash by Washing Machine, Dry-cleaned is allowed.

If there are designs embossed on satin these designs may fade with constant wear.

How to sewing satin?

Shrinkage of satin:

The fabric must be shrinking first time then cut it. The satin fabric shrinkage is high.

Cutting of satin:

Use sharp scissors is mandatory. Make sure to iron the fabric before cutting.

The slippery nature of the fabric makes it difficult to keep its position on the surface. Make sure the surface also is not slippery. Keep pattern weights. Cut single layer only always. If you cut in two layers, the layer underneath will/may definitely shift and you will have a different sized piece.You can keep paper underneath and cut together with the paper. The crispiness of the paper will give some stability to the fabric. You can use rotary cutter and mat also.

3.Needle using on satin:

When sewing satin you have to use very sharp needles.

Microtex (sharp)needles work very well especially for thin satin which may snag with regular needles; Otherwise, a lightweight standard universal point needle would do. A walking foot /even foot is said to be the best for use with slippery fabrics.

4.Thread Using:

Use cotton-wrapped polyester thread, or a lingerie thread for sewing satin fabric.

5.Fusing interlining:

water-soluble fusing interlining: It can be dissolved by water, which is generally used to increase the tension of the fabric when cutting or sewing, and makes it easier to cut and sew.

Some satin need special attention when making, it can’t pull and pull, pulling will cause fabric deformation, so the fusing interlining will be added to prevent deformation at the seams and edges of the fabric.

Lower feed teeth:

The method of transferring the tooth: take the old machine as an example, adjust the delivery tooth to 0.4mm for good, the old machine sends the cloth tooth height, should adjust according to the fabric.

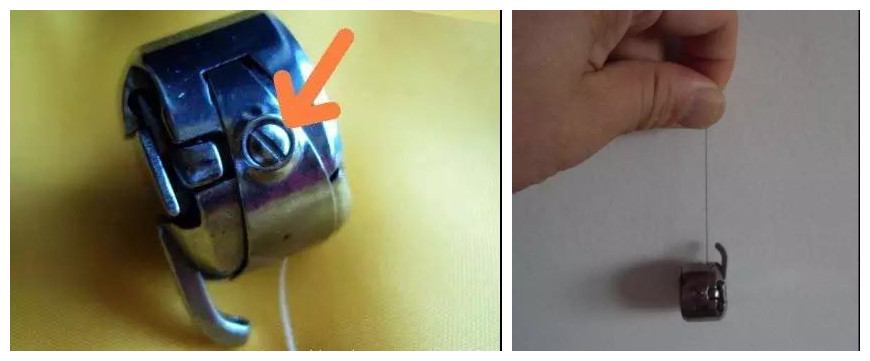

7.Adjust the bobbin pressure of the shuttle core:

Counterclockwise is the tone, clockwise is the tension of the tightening line.

Hold the thread in your hand and shake it gently. The bobbin will slowly drop down, which is more appropriate.

8.Over-locked, piping and binding:

Here is a personal experience of two locks.

The first time to use the universal press, the edge of the fabric is spread out, the zigzag line of the quick car seam;

The second time is to change the edge of the roll, because the edge of the fabric has already passed a car seam, the tension is greatly improved, so the edge becomes much easier.It is easy to roll out the beautiful edges according to the edge method of ordinary thickness fabric.

9.Use a short stitch when stitching satin seams.:

Keep the fabric taut with your left hand as you are sewing satin.

As the fabric may disappear into the needle plate. It is a good idea to test the tension and pressure and stitch length on a test piece first before trying on the final garment. Some also use thin paper on the fabric when sewing.

More details about us, pls check on our website below:

Contact: Jessica Liu

Email: dc@cndc.co

Tel: +86 (020)36012286

Mobile/ WhatsApp: +86 13428886594