How to make your traditional apparel chain into a Quick Response Manufacturing(QRM)?

Five Important Points to choose an appropriate apparel factory

February 3, 2018

Top 3 points of quality control of clothing you should know.

February 3, 2018How to make your traditional apparel chain into a Quick Response Manufacturing(QRM)?

on Feb 3 2018

in Apparel Industry News, Fashion Trends, Supply Chain Managment, Events

How to make your traditional apparel chain into a Quick Response Manufacturing(QRM)?

Since the financial crisis in 2009, the apparel industry chain has matured in the past decade. More and more foreign trade factories gradually turning to domestic trade, together with some trading company transformation, as well as the fabric, accessories traders began to build their own platform. We can say that there are multiple choices in the domestic apparel supply chain.

But depending on the business model, the supply chain has a different model. Some of the processing modes of the supply chain can be self-built, while others need to cooperate. In fact, there are some principles that need to be followed, whether it is self-built or out-of-work. Otherwise, it is not easy to build up the QRM(Quick Response Manufacturing)

1) Steady & JIT Order

What the factory needs most is not the most profitable order, but the stable order.

Therefore, the core principle is “Steady & JIT Order”.

1)In this way, we can establish alliance relationship with the fabric manufacturer and a solid cooperative relationship with the factory.If you don’t have enough orders continued to the factory, so when the factory has no orders, will inevitably find other customers to fill the gap of capacity, when you need the factory to do the goods again, may need to wait a long time.

So how to make proceed steady orders to a cooperated factory is very important.

2)“Order calculation” for cooperative factories

As we know clothing has seasonal characteristics, so it is impossible to always make a very balanced order for every factory. Under the quick response mode, placing a small order the first time, then frequently make re-orders, so that the orders can be relatively balanced.

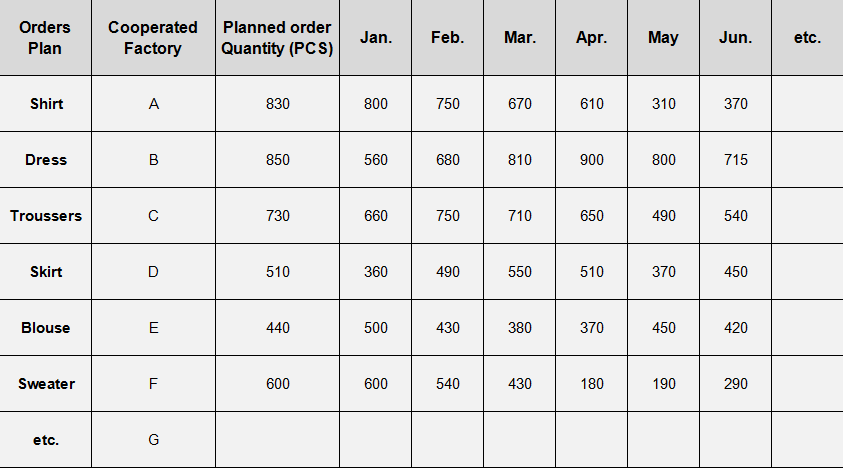

See the form below:

These order plans are also predictive. It is unclear whether the factory can receive so many orders when it comes to order, or whether the price factor is willing to accept it.

So, what’s the point of this “order schedule”?

Its main function is “reserve capacity”. Through this form, we can “place orders” with the factory in advance and make an appointment of 2,000 units next month to arrange the follow-up work.

Moreover, further balance optimization can be done:

- Fixed an order line quantity monthly;

- Confirm the style to be produced next month; Because there is a hot sale at any time will place orders again, so the schedule of the order should be prepared in advance;

- The brand company can specify the order of production and the order of shipment per week (size, color, ratio, etc.)

Basic designs – Fill the gap of factory at any time

The arrangement above is idealized. In fact, due to the fluctuation of design, materials (fabric/accessories), sales condition, etc., there are often no orders for this month, but it may surge next month. So as this situation, we will always prepare some basic designs for the factory.

A brand that has been established for more than 3 years must have its own “dominant category”. Such as coats, trousers, etc., which is characterized by long selling cycle and stable sales. Take advantage of the basic style, in the short gap period of no order, even if the basic style is not sold out, it can be appropriately arranged some quantity of styles to meet the order requirement of the factory.

If your brand doesn’t have a basic design, it’s time to take out the following monthly orders, but this can be an emergency measure only, for long-term planning is not reasonable.

Now some of the fast fashion brands, they will let the factory produce the autumn style in advance while the factory is in the gap period in March.

Conclusion

It is important to note that all quick response mode must be systematically trained, rather than being passive in the hope of finding the right factories. Throughout the mature supply chain of these big brands, all are built and transform of 3-5 years. The brand has put its own requirements into the management mode of the factory, forming a “tacit understanding” of each other and establishing a supply chain system suitable for themselves.

When the brand and the factory well know each other’s needs and cooperate smoothly, the brand can be fully transformed into the garment purchase. Because of the factory already can operate the quick response mode, so the brand he will be much easier to manage the supply chain. They can manage orders through the system and purchase online directly, etc.. This is great for sales, ad it is the ultimate goal of the QRM (Quick Response Manufacturing) supply chain.

More Relate article about DC platform :

1 . What We Do ?

2. DC PLATFORM : New Energy of Apparel Industry – Quick Response Manufacturing

3. Designers & Quality Assurance Updated Of B2B DC Platform

4. How Chinese Use DT (Date Technology) to reforms apparel industry based on IMS and Quick Response?

5. Apparel Supply Chain + Intelligent Store

6. How to operated the Design Interconnection of DC?

7. How DC integrate all resource to make quick response manufacturing of apparel supply chain?

8. How to do fast fashion and where to find the apparel manufacturers?

9. How to use fabric supplier doing ORM ( Quick Response Manufacturing ) mode?

10. Five Important Points to choose an appropriate apparel factroy.